How can chemical industry companies prevent unqualified products from entering the market?

chemical industry companies need to establish a full process quality management system to prevent unqualified products from entering the market, covering the entire process from source control to terminal supervision

Raw Material and Supplier Management

Strict supplier admission mechanism, batch inspection of raw materials and outsourced parts to ensure compliance with quality standards. Establish a blacklist system to eliminate unqualified suppliers.

process control

Equipment maintenance: All production equipment needs to be regularly maintained, and it is prohibited to operate with defects. Immediately shut down the equipment for maintenance upon discovering any abnormalities, and confirm its compliance through the first piece "three inspection system" (operator self inspection, team leader re inspection, quality assurance special inspection) before resuming production.

Personnel training: Operators need to pass job competency certification, and changing positions requires retraining and execution of the first article inspection process.

Process parameter control: Key processes such as welding current, time, and other parameters need to be standardized, and operating specifications should be clarified through process documents.

Quality inspection and isolation

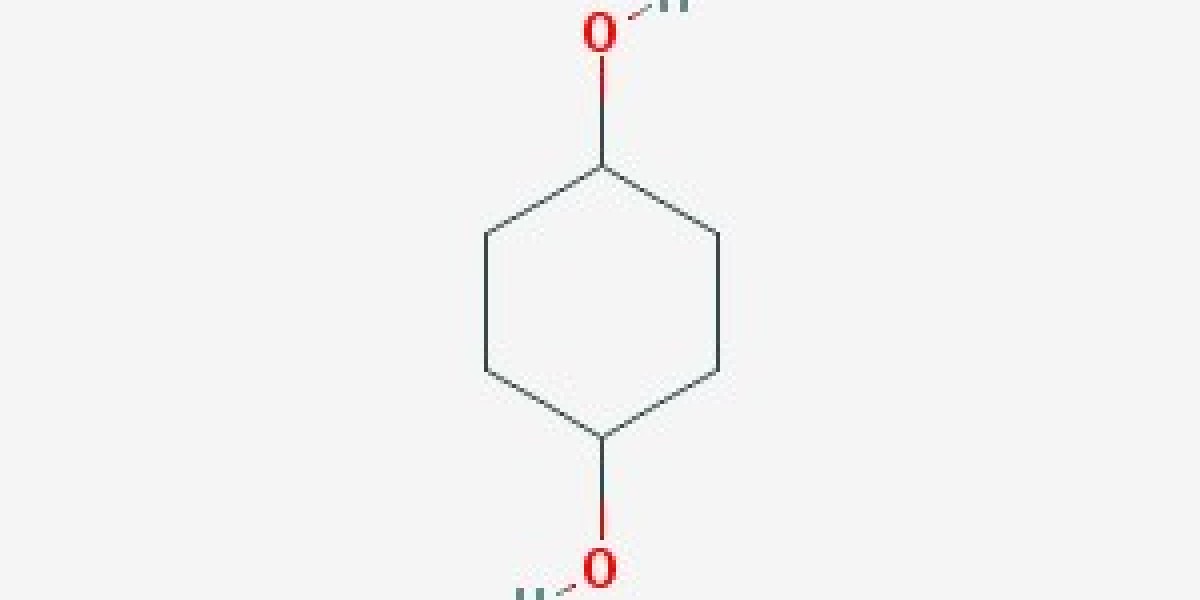

Inspection process: Implement a full process sampling and final inspection system, with key testing items including component analysis, stability testing, and residual detection of harmful substances.

Isolation of non-conforming products: If non-conforming products are found, they should be immediately marked and isolated for storage. The batch, quantity, and reason for the non-conforming products should be recorded to prevent the mixing of qualified products.

Terminal Management and Emergency Response

Packaging and labeling: Product packaging must comply with national safety standards, with labels indicating ingredients, warning language, and emergency response methods.

Warehouse management: Establish a first in, first out system, regularly check the shelf life and storage conditions of inventory products, and avoid quality problems caused by improper storage.

Regulatory compliance

Strictly implement the "Dust Explosion Prevention Safety Regulations" and other chemical industry standards, regularly conduct safety self inspections (such as dust removal system bridging, tank fire protection embankment setting, etc.), and ensure that the production environment meets safety standards.